Story at a glance:

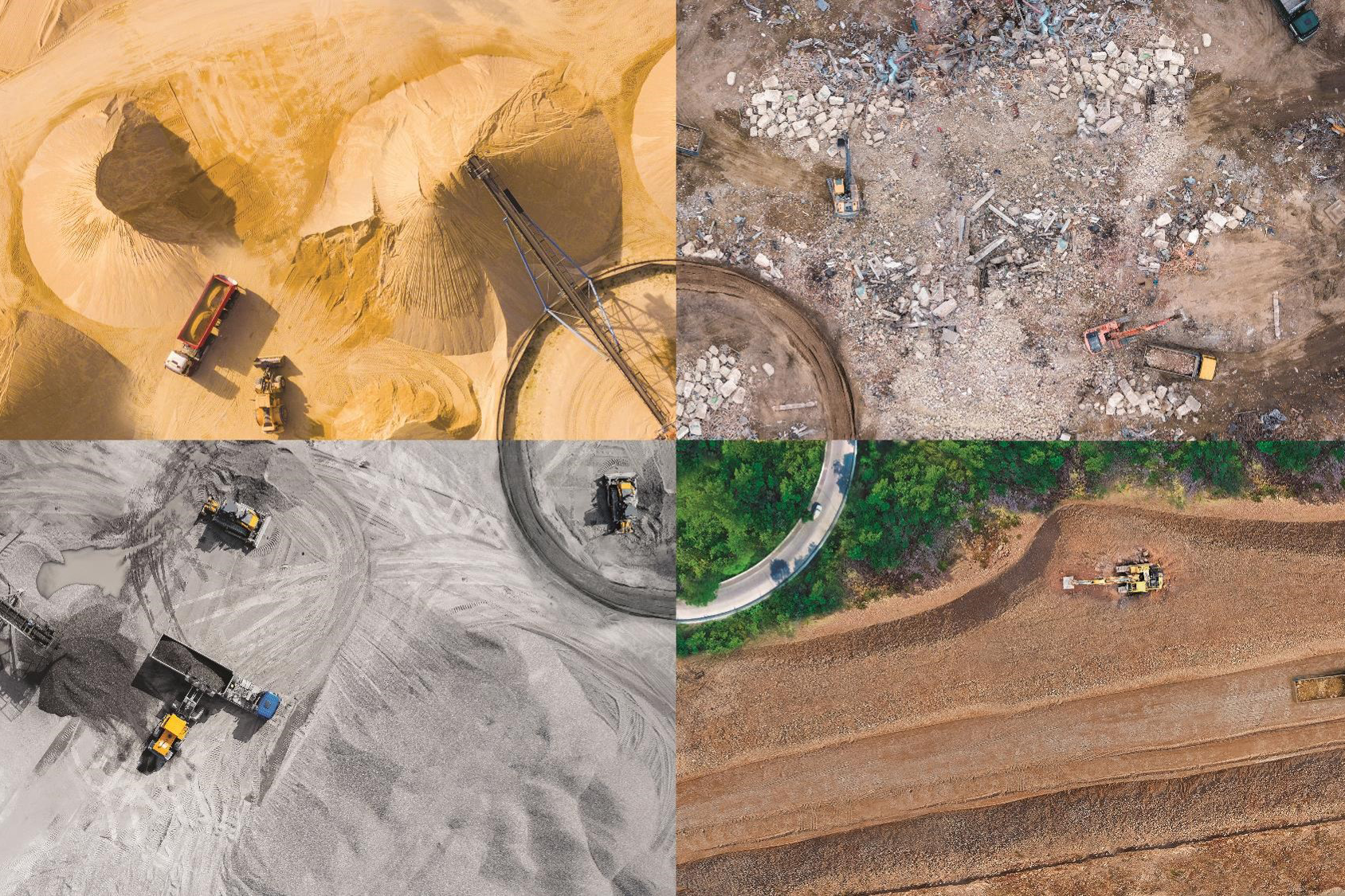

- The construction industry is a significant contributor to greenhouse gas emissions.

- CHRYSO and GCP develop new technologies that help to reduce energy consumption, lower the carbon footprint of cements and concrete, and foster the circular economy.

The UN Climate Change Conference COP28 closed in December and included the release of “State of Decarbonization: Progress in U.S. Commercial Buildings 2023.” It may come as no surprise that the report indicates achieving US climate goals will require deep reductions across the US commercial real estate sector. The report provides key data and strategies for reducing buildings’ carbon emissions.

Some manufacturers, like CHRYSO and GCP (Saint-Gobain Construction Chemicals), have long been focused on sustainable construction with a portfolio of concrete admixtures and cement additives well-positioned to assist the industry on its journey to carbon neutrality by 2050.

We recently talked with Lisa Barnard, sustainability and customer engagement program manager for CHRYSO & GCP, about why it’s important to them to lower carbon—and how that’s ongoing now.

Why is the carbon conversation more important than ever?

GHG emissions by sector according to the “State of Decarbonization: Progress in U.S. Commercial Buildings 2023” report. Image courtesy of USGBC

The construction industry is a significant contributor to greenhouse gas emissions. And traditional concrete has long been a major contributor to carbon emissions due to the energy-intensive production of cement. It is our responsibility as a worldwide leader in the construction industry to develop new technologies for sustainable construction that play a critical role in helping to reduce energy consumption, lower the carbon footprint of cements and concrete, and foster the circular economy.

How does that factor into CHRYSO and GCP’s mission?

We are aligned with Saint-Gobain’s purpose of “Making the World a Better Home.” Enabling concrete and cement producers to reduce their carbon footprint and extend the life of their projects makes an exponential difference around the world.

We partner with our customers throughout the cement and concrete life cycle, enabling them to achieve their technical, business, and sustainable objectives. We are focused on delivering solutions that not only reduce carbon throughout the life cycle of concrete but also deliver resiliency and performance.

What solutions show this mission in action?

The integration of CHRYSO & GCP creates a vast depth of R&D expertise and technical know-how, alongside recent technologies for sustainable construction.

CHRYSO®Quad is one of our more recent solutions to assist the industry in achieving technical, business, and sustainable objectives. The innovative product offerings enable the use of lower quality, locally sourced or manufactured sands without compromising concrete quality, while improving the concrete CO2 footprint.

Another example is EnviroMix® SE—a novel class of strength enhancers for concrete. The next generation admixture solution plays a key role in Saint-Gobain’s commitment to the decarbonization of construction.

EnviroMix SE is part of EnviroMix—the first global range of innovative products and services aimed at reducing and controlling the carbon footprint of concrete. EnviroMix SE is the inventive strength enhancer for concrete that reduces the cement factor by approximately 10% in addition to the water reducer while maintaining premium concrete quality and performance. Water reducers are a powerful solution to reduce cement factor, but they can reach limits. EnviroMix SE is a powerful solution to further reducing cement and carbon while increasing the strength of concrete.

What does eco-innovation mean?

Our eco-innovation approach is to reduce the amount of carbon in concrete throughout the product life cycle. This means starting at the macro level by working with stakeholders to optimize design, delivery, and service life while also addressing the micro level to optimize materials,through chemistry and intricate life cycle analysis. This two-level approach allows us to make the most eco-efficient choices.

How have sustainability efforts evolved there?

There are tremendous opportunities/efforts engaged already to reduce the carbon footprint of concrete throughout its life cycle by and not only:

Increasing concrete performance through mix optimization strategies, which can include lowering the cement content

Sourcing locally available aggregates

Reducing rejected concrete loads through the automation of slump management

Treating returned concrete to reduce waste

Optimizing production processes to reduce the energy and water consumption

Evolving construction practices to use less steel reinforcement systems potentially using synthetic fibers instead

Extending the life of concrete structures.

CHRYSO & GCP provide solutions for all these efforts and work hand-in-hand with our customers to maximize their impacts.

Why is low carbon concrete important?

The production of cement contributes an estimated 85 to 90% of concrete’s carbon footprint. CO2 is produced during a chemical reaction that takes place when cement is being manufactured. In addition, the high-heat kilns used to produce cement run on fossil fuels, which results in more CO2 emissions.

We evaluate the entire life cycle of concrete, including cement, to make an impact on its carbon footprint. Thanks to the long life of concrete structures, the finished product has one of the lowest environmental footprints. Reducing the carbon footprint of the production of concrete even further will contribute significantly to reducing the construction environmental footprint, as concrete remains the most used construction material on earth.

What’s next for low carbon concrete?

The journey toward low carbon concrete is an ongoing process marked by continuous research and development and construction standards evolution. One promising avenue of research involves exploring new sources of supplementary cementitious materials, like natural and glass pozzolans and blended cements. These materials have the potential to further reduce the carbon footprint of concrete and offer additional benefits, such as improved durability and reduced permeability.

As a cement additive and concrete admixture supplier, it is key to partner with our customers to address the new and very specific challenges generated by these lower carbon materials.

What are other signs of sustainability at CHRYSO & GCP?

We use LCAs and EPDs both internally and externally for product development and transparency. In the journey toward carbon neutrality it is important to provide accurate and robust data. To that end we work with third-party providers to assist our customers in the development of their own LCA and ultimately mix specific concrete EPDs using our admixture specific data.